Multitex: a new innovative way of recycling textile waste without treatment systems

Project details

- Main leader : VALAGRO Carbone Renouvelable

- Type of initiative : Initiative involving different people (collective, etc.)

- Périmètre : Territoire "Grand Ouest"

- Localisation : 4, Rue Marcel Doré - 86000 Poitiers

- Date de début : janvier 2010

- Date de fin : mars 2016

Economy circular topics

- Recycling

- Eco-design

- Extending useful service life

- Responsible consumption

- Functional service economy

- Industrial and regional ecology

- Sustainable procurement

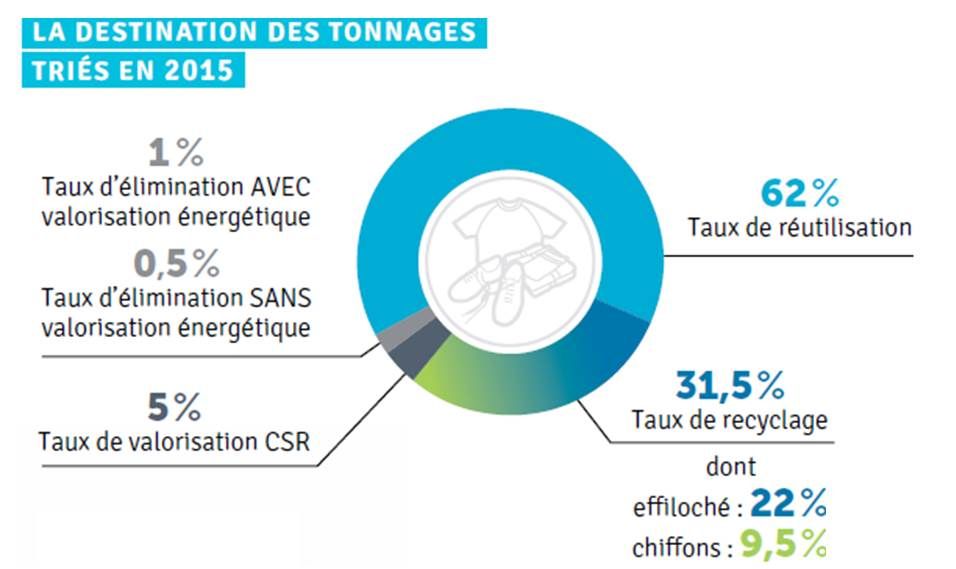

Around 600,000 tonnes of textiles, linen and footwear are sold in France each year, of which 200,000 tonnes are collected. 62% are reused, 37.5% are recycled and used for energy, and 0.5% cannot be recovered. There are over 24 different types of textile materials: these may be found mixed together in the same article (Source: ECO-TLC)

The method provides a new way of recycling the materials treated for energy recovery and offer new opportunities for operators collecting, sorting and recycling textiles. It also makes it possible to assess the potential environmental benefits as compared to current treatment solutions.

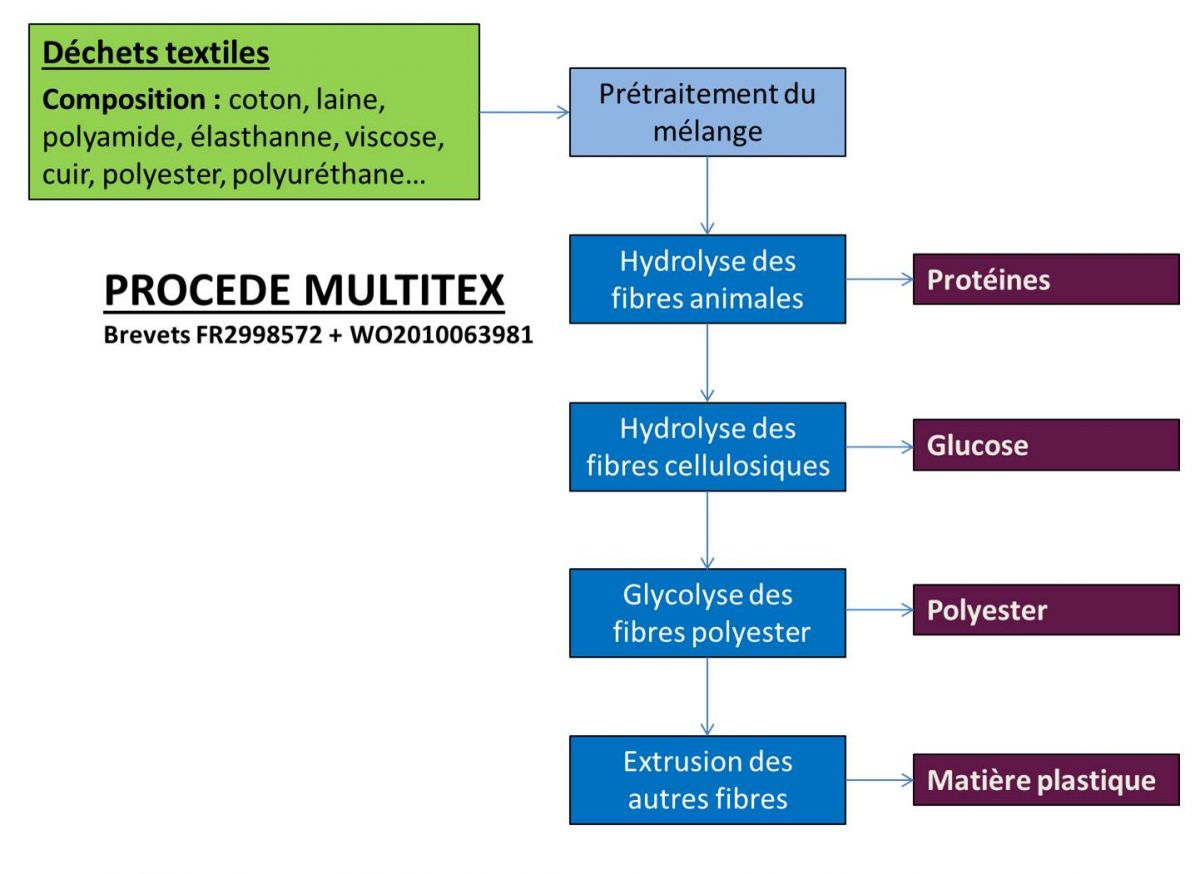

The method is used to process batches of multi-material textile scrap by attacking it with successive selective depolymerization reactions.

It comprises the following 4 steps:

- Enzymatic hydrolysis of animal fibres (wool and silk) into peptides (amino acids),

- Enzymatic hydrolysis of cellulose fibres (cotton) into sugar juices (glucose),

- Glycolysis of polyester fibres into BHET (bis-hydroxyethyl terephthalate) crystals, a monomer of PET,

- Extrusion of the remaining textile for recovery as a new raw material for use in plastics, after adding additives.

From textile mixture batches of all kinds, we create individual chemical reactions depending on the types of materials. This method is used to isolate compounds one after another and generate molecules with a high added value: protein, glucose and plastic. We can selectively treat all mixed materials and provide an outlet for used textiles that do not currently have any recycling solutions.

We have successfully deployed the process as a pilot with different batches of 100kg of multi-material textiles with the following compositions: cotton, polyester, polyamide, acrylic, polypropylene, spandex, wool, silk, leather, viscose, cellulose acetate, PVC, polyacrylic and modal

The results show that the move to industrial production is now possible for complete recycling of treated textiles and in all forms, to obtain molecules already used as intermediates in industrial chemistry.

Qualitative benefits

This unique method of treating textile mixtures has yielded four main types of recycled materials with attractive opportunities: animal fibres such as wool, leather and silk are hydrolysed to form proteins, cotton fibre is turned into glucose (sugar juice) and polyester into bis-hydroxyethyl-terephthalate (BHET) monomers. The final residue made up of other synthetic fibres such as nylon, acrylic, and spandex, is recovered as a reinforcement for use in the plastics industry.

This project offers not only an interesting, innovative method for the recovery of much textile waste currently without specific opportunities (energy recovery, incineration or landfill), but it is also a particularly valuable solution from the environmental standpoint as confirmed by the results of a study conducted by the Pôle des Eco-Industries.

Stages of the initiative

2009: synthetic mono-material textiles (polyester, polyamide, acrylamide) were transformed by successive stages of crushing, compacting and extruding into a raw material for the plastics industry (financed by OSEO)

2010: textiles made of cotton and viscose were processed by grinding and fermentation into bioethanol fuel (funded by ADEME)

2011: study on the depolymerization of polyesters by solvolysis.

2012 - 2013: depolymerization of textiles made of different materials and of different origins (synthetic and natural) by biochemical hydrolysis of natural fibres and by solvolysis was validated in laboratory (Multitex project, co-funded by ECO TLC).

2012: The method is protected by patents FR2998572 + WO2010063981

2014 - 2016: the method was improved through various phases:

- Supply and sampling of textile materials, and preparation of batches

- Optimization of each stage and the overall process in laboratory

- Method tested as an industrial pilot

- Environmental assessment and economic study with a view to industrial development of the process

Driving forces: knowledge of regional networks and issues encountered by those involved, support for R&D programmes from eco-organizations, complementary action by people involved in circular economy in the region.

Obstacles: identification of the exact composition of the textile materials (the labels cannot always be read, if there are any), development of new textile materials

Areas of activity

- Chemistry

- Industry

- Recycling

Resources

- Materials

- Waste

- Chemicals

- Material efficiency

- Energy efficiency

- Plastic

- Textiles

Technical resources

Secondary raw materials: textiles sorted by material and to remove "hard" points such as buttons and zips, industrial cutters

Laboratory facilities: cutting mill, pulverizer, granulating machine, chemical reactors with capacities from 1 to 100L, separation tools, dryers and characterization appliances (humidity, chromatography, calorimeter).

Pilot installation: cutting mill, weigh feeder, extruder, screw conveyor, 2 m3 tanks, screw press, impregnator, centrifugal decanter

Human resources

Staff from the various partner organizations of the project

Financers

- ECO TLC

Support from ECO TLC (the linen, textile and footwear environmental body) amounting to €112,917 as R&D projects with support of 50%.

Funding

Joint funding from ECO TLC and resources from each partnerWeb link(s)

www.valagro-rd.comwww.ecoethanol.fr

www.valoristextile.com

www.pole-ecoindustries.fr

http://www.resyntex.eu/